All knives are manufactured from chrome nickel tool steel as standard, but when processing applications that are particularly abrasive the DGP granulators can be fitted with a specially designed wear resistant rotor utilizing wear resistant steel parts and hardox facing.

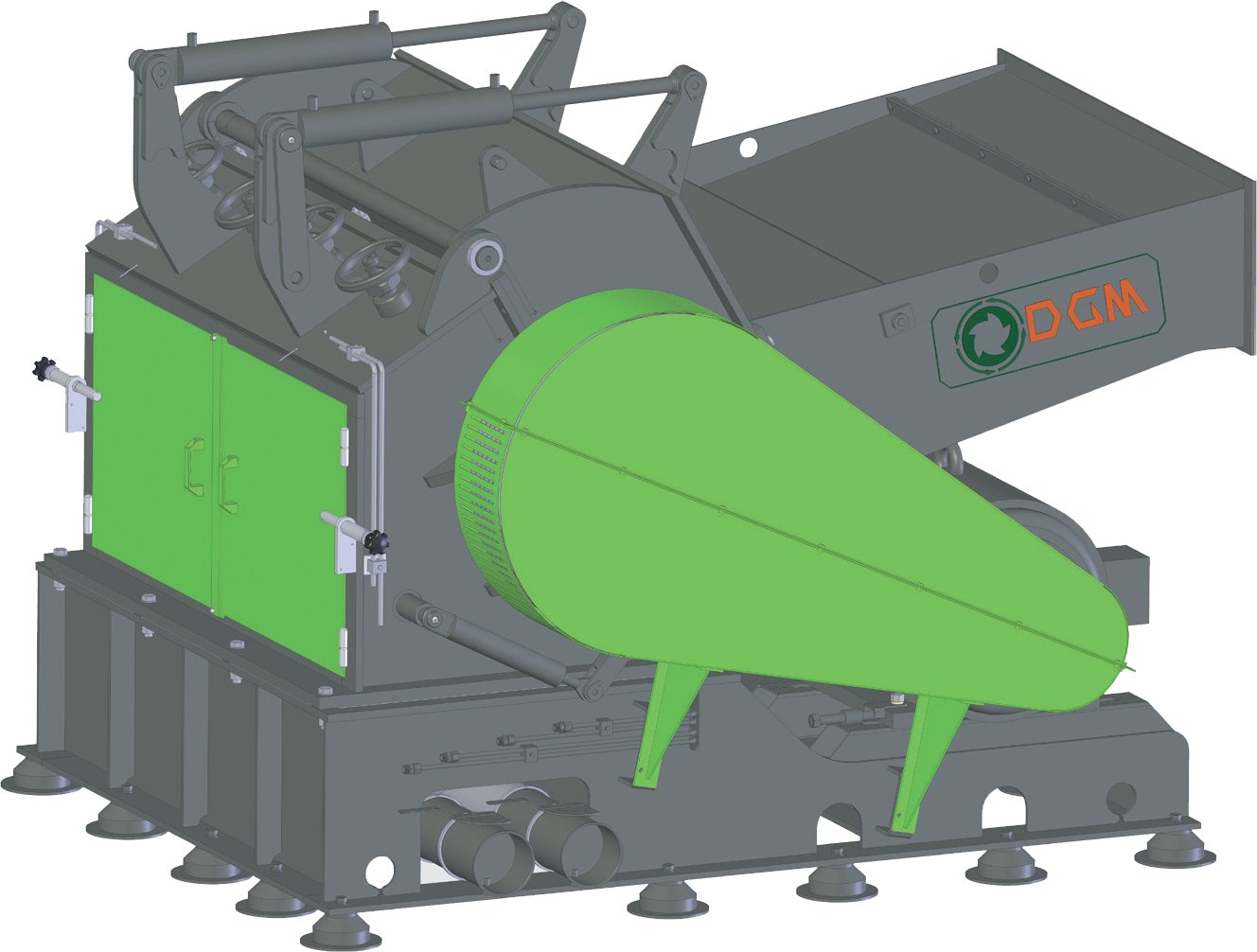

The v-cut cutting geometry offers distinct advantages over other rotor designs, including higher throughput with reduced power consumption, better quality cut, and lower noise levels. Specially designed knife setting jig means that the knives can be adjusted from outside the machine, significantly reducing the downtime required to change/set knives. The base frame has a solid welded construction with anti-vibration rubber feet to reduce vibration and noise. The drive motor is mounted on tension rails to allow easy adjustment of the V-belt tension. Integrated suction trough for material discharge.

Integrated rundown safety device prevents access to the rotor until it has come to a complete stop. A safety switch prevents machine startup when the front panel is open and the machine features emergency stop buttons on the machine body and control panel.

APPLICATIONS

DGP Pipe/Profile Granulators have been designed with a wide range of applications and industries in mind such as:

PLASTICS / WOOD (specifically long lengths of material such as pipes, profiles, sheets, etc.)

SPECIFICATION

MODEL | | 600/500 | 560/700 | 560/1000 | 700/1400 |

Infeed opening | mm | 440x440 | 640x280 | 910x280 | 1440x320 |

Rotor diameter | mm | 600 | 560 | 560 | 700 |

Rotor speed | rpm | 560 | 470 | 470 | 410 |

Main motor power | kW | 37 - 45 | 55 - 75 | 75 - 90 | 90 -110 |

Rotor knives | pcs | 5x2 | 5x2 | 5x2 | 5x2/7x2 |

Stator knives | rows | 2 | 2 | 2 | 2 |

Hydraulic Ram power | kW | 1,5 | 1,5 | 1,5 | 1,5 |

Screen size | mm | 6 -30 | 6 - 30 | 6 – 30 | 8 -30 |

Effective working area | mm | 516x498 | 716x650 | 985x650 | 1400x700 |

Dimensions | A | mm | 2250 | 2400 | 2400 | 2480 |

B | mm | 1860 | 2200 | 2200 | 2320 |

C | mm | 1350 | 1800 | 2050 | 2400 |

D | mm | 820 | 1060 | 1480 | 1840 |

E | mm | 1620 | 1750 | 1750 | 1980 |